Installation method of stainless steel eccentric reducer at pump inlet

Let’s briefly introduce the function of stainless steel reducers in stainless steel pipe fittings: used to change the size of the pipe diameter. Then changing the size of the pipe diameter at the inlet and outlet of the pump is mainly to reduce the flow rate of the medium in the pipe, and reduce the flow rate to reduce the friction when the medium flows in the pipe. Due to its special eccentric properties, stainless steel eccentric reducers have different installation methods under different installation conditions. The following is a brief introduction to several installation methods of stainless steel eccentric reducers.

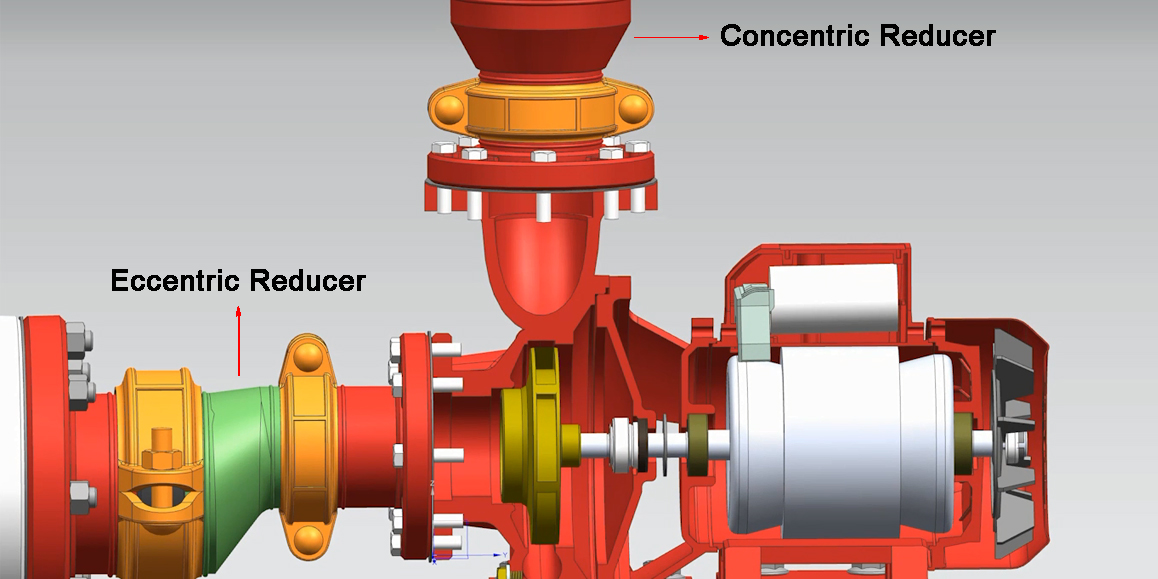

The stainless steel eccentric reducer at the inlet of the centrifugal pump is generally installed with the top flat. However, when the stainless steel eccentric reducer is directly connected to an upwardly bent elbow, the bottom flat installation can be selected.

The reason why the stainless steel eccentric reducer is installed flat on the top is to prevent gas from accumulating in the eccentric reducer and entering the centrifugal pump, causing cavitation damage to the pump.

Regarding the installation of the stainless steel eccentric reducer on the inlet pipe of the end-suction centrifugal pump (that is, the pump inlet is a horizontal inlet), in the textbook on pump piping standards, it is stipulated as follows: The diameter orientation of the eccentric reducer on the horizontal pipe (Whether the horizontal part is upward or downward) is determined by whether a liquid bag or air bag appears (divided into two situations):

1. When the medium enters the pump from top to bottom, the eccentric reducer is installed with a flat bottom to prevent the occurrence of liquid bags;

2. When the medium enters the pump from bottom to top, the eccentric reducer is installed with the top flat to prevent the occurrence of air bags;