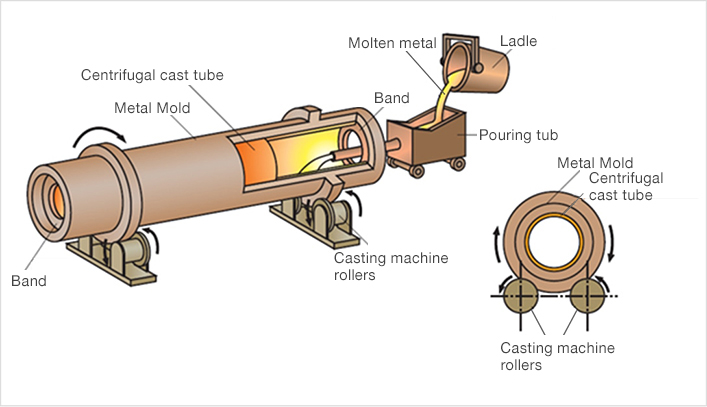

Stainless steel flange casting process - centrifugal casting method

We inject the metal liquid into the high-speed rotating mold, use centrifugal force to evenly spread it on the inner wall, and after it solidifies, the required stainless steel flange casting method is called the stainless steel flange centrifugal casting method. Compared with ordinary sand casting, this casting method has a much finer structure, much improved quality, and is less prone to problems such as loose tissue, pores, and trachoma.

The following will introduce the process flow of producing stainless steel flanges by centrifugal method:

①Put the selected stainless steel into the medium frequency electric furnace for smelting to turn it into molten steel;

② Preheat the stainless steel flange mold and keep it at a constant temperature;

③Start the centrifuge and inject the molten steel in step ① into the preheated stainless steel flange mold in step ②;

④ After continuous rotation, cool naturally to 800-900℃ and hold for 1-10 minutes;

⑤ Cool with water to close to normal temperature, demould and take out the stainless steel flange.

⑥Use a lathe to remove impurities on the inner wall and process the required screw holes.