01

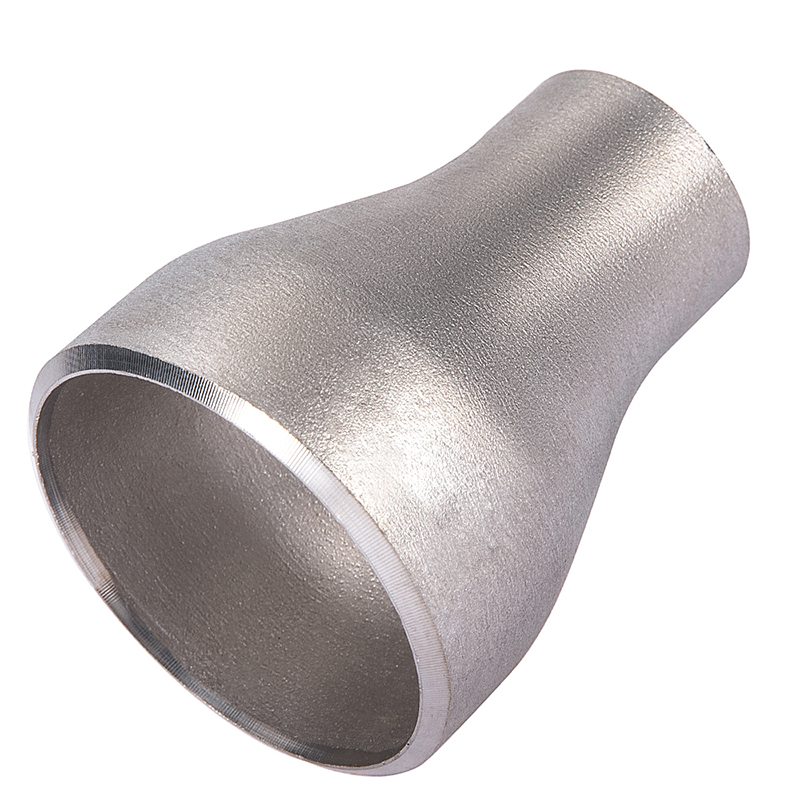

Stainless Steel Butt Weld Concentric Reducers

Video Introduction

| Product Name | Stainless Steel Butt Weld Concentric Reducers |

| Standard | ASTM A213, ASTM A312, ASTM A789, ASTM A790 |

| Material Grade | 304/316L/2205 etc. |

| NPS | 3/4″-60″ |

| Outer Diameter | 26.9mm-1524mm |

| Thickness | 2mm-20mm |

| Connection method | Butt Welded |

| Surface | Sand blasting/Sand rolling |

| Brushed/Mirror:400#, 600#, 800# or more | |

| Packing | Plastic bag/woven packing |

| Woven bags/Wooden boxes and other packaging methods. |

Product Introduction

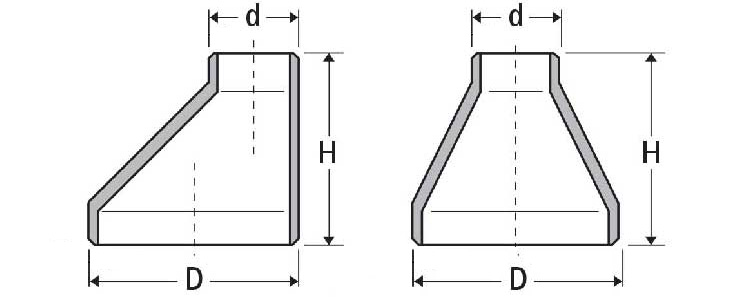

| D-d | H/mm | ||

| DN | NPS | OD/mm | |

| 20-10 | 3/4-3/8 | 26.9-17.2 | 38 |

| 20-15 | 3/4-1/2 | 26.9-21.3 | 38 |

| 25-15 | 1″-1/2 | 33.7-21.3 | 51 |

| 25-20 | 1″-3/4 | 33.7-26.9 | 51 |

| 32-15 | 1″ 1/4-1/2 | 42.4-21.3 | 51 |

| 32-20 | 1″ 1/4-3/4 | 42.4-26.9 | 51 |

| 32-25 | 1″ 1/4-1″ | 42.4-33.7 | 51 |

| 40-15 | 1″ 1/2-1/2 | 48.3-21.3 | 64 |

| 40-20 | 1″ 1/2-3/4 | 48.3-26.9 | 64 |

| 40-25 | 1″ 1/2-1″ | 48.3-33.7 | 64 |

| 40-32 | 1″ 1/2-1″ 1/4 | 48.3-42.4 | 64 |

| 50-20 | 2″-3/4 | 60.3-26.9 | 76 |

| 50-25 | 2″-1″ | 60.3-33.7 | 76 |

| 50-32 | 2″-1″ 1/4 | 60.3-42.4 | 76 |

| 50-40 | 2″-1″ 1/2 | 60.3-48.3 | 76 |

| 65-25 | 2″ 1/2-1″ | 76.1-33.7 | 90 |

| 65-32 | 2″ 1/2-1″ 1/4 | 76.1-42.4 | 90 |

| 65-40 | 2″ 1/2-1″ 1/2 | 76.1-48.3 | 90 |

| 65-50 | 2″ 1/2-2″ | 76.1-60.3 | 90 |

| 80-32 | 3″-1″ 1/4 | 88.9-42.4 | 90 |

| 80-40 | 3″-1″ 1/2 | 88.9-48.3 | 90 |

| 80-50 | 3″-2″ | 88.9-60.3 | 90 |

| 80-65 | 3″-2″ 1/2 | 88.9-76.1 | 90 |

| 90-40 | 3″ 1/2-1″ 1/4 | 101.6-42.4 | 102 |

| 90-50 | 3″ 1/2-1″ 1/2 | 101.6-48.3 | 102 |

| 90-65 | 3″ 1/2-2″ | 101.6-60.3 | 102 |

| 90-80 | 3″ 1/2-2″ 1/2 | 101.6-73.0 | 102 |

| 100-40 | 4″-1″ 1/2 | 114.3-48.3 | 102 |

| 100-50 | 4″-2″ | 114.3-60.3 | 102 |

| 100-65 | 4″-2″ 1/2 | 114.3-73.0 | 102 |

| 100-80 | 4″-3″ | 114.3-88.9 | 102 |

| 100-90 | 4″-3″ 1/2 | 114.3-101.6 | 102 |

| 125-50 | 5″-2″ | 141.3-60.3 | 127 |

| 125-65 | 5″-2″1/2 | 141.3-73.0 | 127 |

| 125-80 | 5″-3″ | 141.3-88.9 | 127 |

| 125-90 | 5″-3″1/2 | 141.3-101.6 | 127 |

| 125-100 | 5″-4″ | 141.3-114.3 | 127 |

| 150-65 | 6″-2″ 1/2 | 168.3-73.0 | 140 |

| 150-80 | 6″-3″ | 168.3-88.9 | 140 |

| 150-90 | 6″-3″ 1/2 | 168.3-101.6 | 140 |

| 150-100 | 6″-4″ | 168.3-114.3 | 140 |

| 150-125 | 6″-5″ | 168.3-141.3 | 140 |

| 200-90 | 8″-3″ 1/2 | 219.1-101.6 | 152 |

| 200-100 | 8″-4″ | 219.1-114.3 | 152 |

| 200-125 | 8″-5″ | 219.1-141.3 | 152 |

| 200-150 | 8″-6″ | 219.1-168.3 | 152 |

| 250-100 | 10″-4″ | 273.0-114.3 | 178 |

| 250-125 | 10″-5″ | 273.0-141.3 | 178 |

| 250-150 | 10″-6″ | 273.0-168.3 | 178 |

| 250-200 | 10″-8″ | 273.0-219.1 | 178 |

| 300-125 | 12″-5″ | 323.9-141.3 | 203 |

| 300-150 | 12″-6″ | 323.9-168.3 | 203 |

| 300-200 | 12″-8″ | 323.9-219.1 | 203 |

| 300-250 | 12″-10″ | 323.9-273.0 | 203 |

| 350-150 | 14″-6″ | 355.6-168.3 | 330 |

| 350-200 | 14″-8″ | 355.6-219.1 | 330 |

| 350-250 | 14″-10″ | 355.6-273.0 | 330 |

| 350-300 | 14″-12″ | 355.6-323.9 | 330 |

| 400-200 | 16″-8″ | 406.4-219.1 | 356 |

| 400-250 | 16″-10″ | 406.4-273.0 | 356 |

| 400-300 | 16″-12″ | 406.4-323.9 | 356 |

| 400-350 | 16″-14″ | 406.4-355.6 | 356 |

| 450-250 | 18″-10″ | 457-273.0 | 381 |

| 450-300 | 18″-12″ | 457-323.9 | 381 |

| 450-350 | 18″-14″ | 457-355.6 | 381 |

| 450-400 | 18″-16″ | 457-406.4 | 381 |

| 500-300 | 20″-12″ | 508-323.9 | 508 |

| 500-350 | 20″-14″ | 508-355.6 | 508 |

| 500-400 | 20″-16″ | 508-406.4 | 508 |

| 500-450 | 20″-18″ | 508-457 | 508 |

| 550-350 | 22″-14″ | 559-355.6 | 508 |

| 550-400 | 22″-16″ | 559-406.4 | 508 |

| 550-450 | 22″-18″ | 559-457 | 508 |

| 550-500 | 22″-20″ | 559-508 | 508 |

| 600-400 | 24″-16″ | 610-406.4 | 508 |

| 600-450 | 24″-18″ | 610-457 | 508 |

| 600-500 | 24″-20″ | 610-508 | 508 |

| 600-550 | 24″-22″ | 610-559 | 508 |

| 650-450 | 26″-18″ | 660-457 | 610 |

| 650-500 | 26″-20″ | 660-508 | 610 |

| 650-550 | 26″-22″ | 660-559 | 610 |

| 650-600 | 26″-24″ | 660-610 | 610 |

| 700-500 | 28″-20″ | 711-508 | 610 |

| 700-550 | 28″-22″ | 711-559 | 610 |

| 700-600 | 28″-24″ | 711-610 | 610 |

| 700-650 | 28″-26″ | 711-660 | 610 |

| 750-550 | 30″-22″ | 762-559 | 610 |

| 750-600 | 30″-24″ | 762-610 | 610 |

| 750-650 | 30″-26″ | 762-660 | 610 |

| 750-700 | 30″-28″ | 762-711 | 610 |

| 800-600 | 32″-24″ | 813-610 | 610 |

| 800-650 | 32″-26″ | 813-660 | 610 |

| 800-700 | 32″-28″ | 813-711 | 610 |

| 800-750 | 32″-30″ | 813-762 | 610 |

| 850-650 | 34″-26″ | 864-660 | 610 |

| 850-700 | 34″-28″ | 864-711 | 610 |

| 850-750 | 34″-30″ | 864-762 | 610 |

| 850-800 | 34″-32″ | 864-813 | 610 |

| 900-650 | 36″-26″ | 914-660 | 610 |

| 900-700 | 36″-28″ | 914-711 | 610 |

| 900-750 | 36″-30″ | 914-762 | 610 |

| 900-800 | 36″-32″ | 914-813 | 610 |

| 900-850 | 36″-34″ | 914-864 | 610 |

See more sizes here

Knowledge Expansion

The nozzles at both ends of the eccentric large and small heads are inscribed in the circumference and are generally used for horizontal liquid pipelines; the centers of the nozzles at both ends of the concentric large and small heads are on the same axis and are generally used for diameter reduction of gas or vertical liquid pipelines. It is also used to reduce the diameter of pipes or flanges of different diameters.

For details, click "The difference between eccentric large and small heads and concentric large heads"Factory Profile

Factory exterior

10,000+㎡Factory area/30+ years of stainless steel production experience

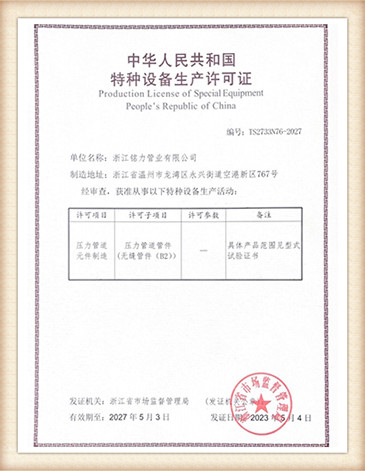

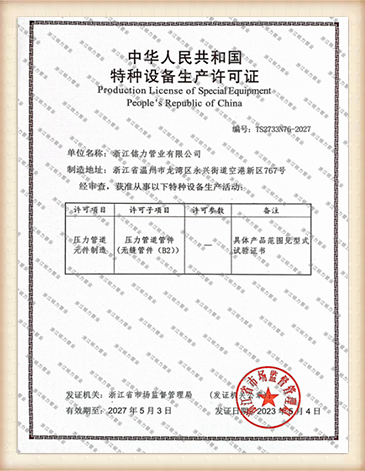

certificate display

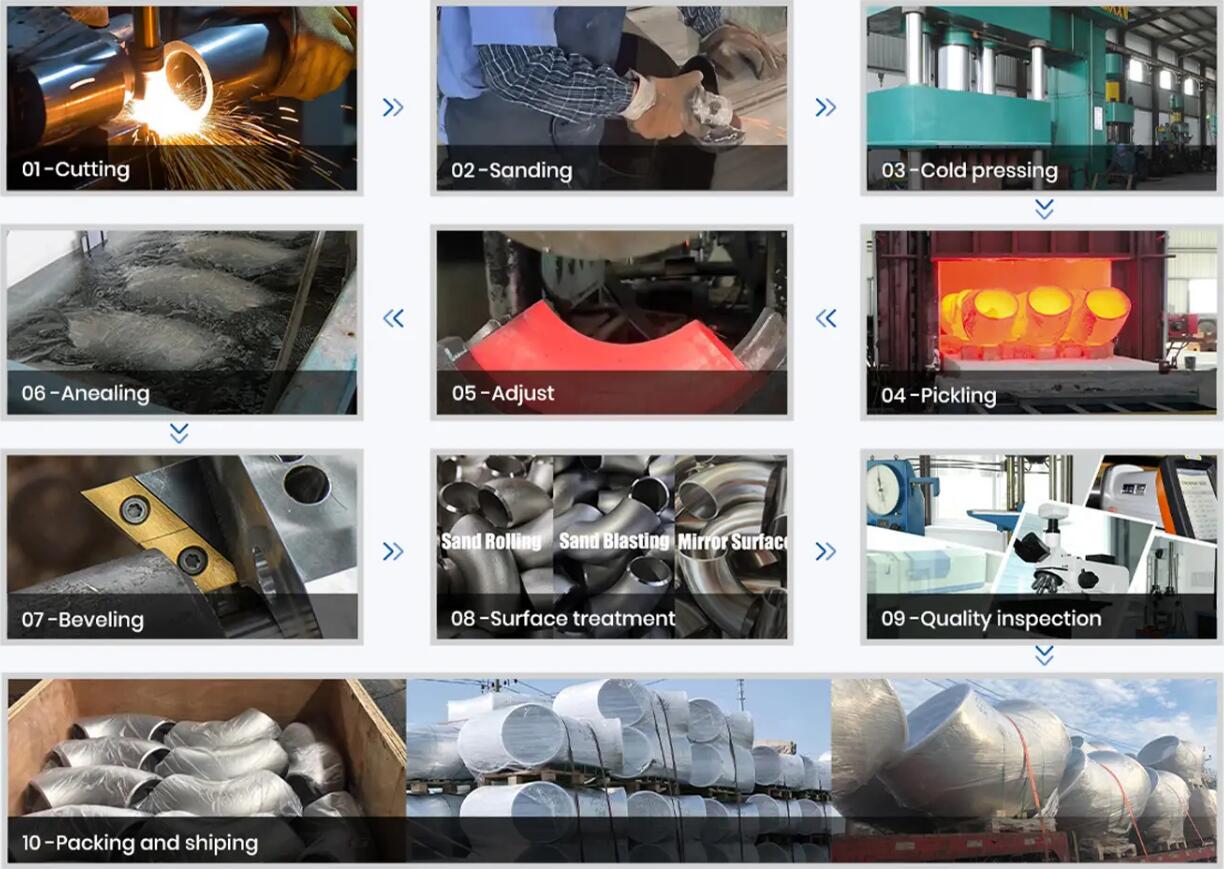

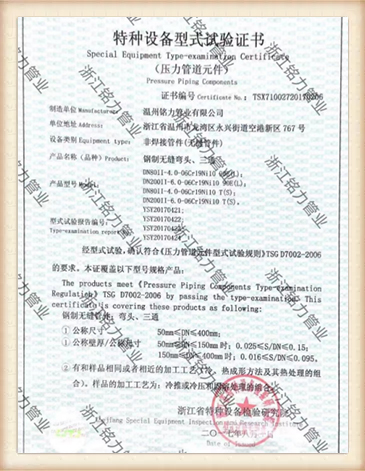

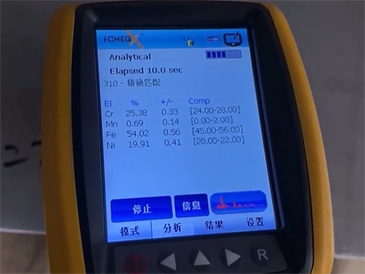

Production line display

Production caliber: DN15-DN2500

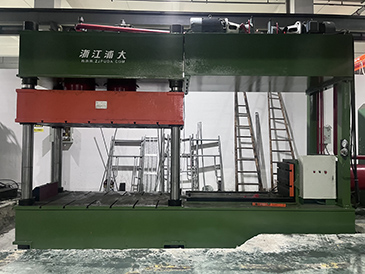

Product testing display

Support third party detection

Spot inventory display

800+ tons in stock, fast delivery

Delivery display

Ensure beautiful delivery of products

FAQ

Q1: Can you provide samples?

Of course, We can provide a few sample tubes for you to inspect and experiment.

Q2: Can we mark our logo on the product?

Yes,You can choose inkjet marking or laser marking.

Q3: What is your packing?

Woven bags/Wooden boxes/Wooden reel/Iron reel and other packaging methods.

Q4: What inspections will be done before the product is shipped?

In addition to routine surface and dimensional inspections. We will also perform non-destructive testing such as PT, UT, PMI.

Q5: What is your minimum order quantity (MOQ)?

Different products have different minimum order quantities, you can consult for details.

Q6: How long is the delivery time?

In stock: 5-7 days.

We also support non-standard customization. If it is a customized product, the delivery time will be determined according to the product category.