Stainless Steel ReducingTee Tumbled Sand Surface

Video Introduction

| Product Name | Stainless Steel Reducing Tee |

| Standard | ASTM A213, ASTM A312, ASTM A789, ASTM A790 |

| Material Grade | 304/316L/2205 etc. |

| NPS | 1/2”-60” |

| Outer Diameter | 21.3mm-1524mm |

| Connection method | Butt Welded |

| Surface | Sand blasting/Sand rolling |

| Brushed/Mirror:400#, 600#, 800# or more | |

| Packing | Plastic bag/woven packing |

| Woven bags/Wooden boxes and other packaging methods. |

Product Introduction

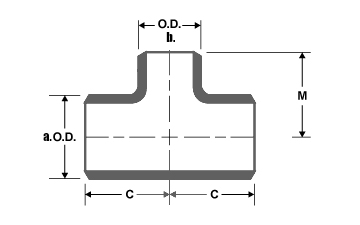

| DN | NPS | a.O.D | B.O.D | C | M |

| 15x8 | 1/2x1/4 | 21.3 | 13.5 | 25 | 25 |

| 15x10 | 1/2x3/8 | 21.3 | 17.2 | 25 | 25 |

| 20x10 | 3/4x3/8 | 26.9 | 17.2 | 29 | 29 |

| 20x15 | 3/4x1/2 | 26.9 | 21.3 | 29 | 29 |

| 25x15 | 1″x1/2 | 33.7 | 21.3 | 38 | 38 |

| 25x20 | 1″x3/4 | 33.7 | 26.9 | 38 | 38 |

| 32x15 | 1″1/4x1/2 | 42.4 | 21.3 | 48 | 48 |

| 32x20 | 1″1/4x3/4 | 42.4 | 26.9 | 48 | 48 |

| 32x25 | 1″1/4x1″ | 42.4 | 33.7 | 48 | 48 |

| 40x15 | 1″1/2x1/2 | 48.3 | 21.3 | 57 | 57 |

| 40x20 | 1″1/2x3/4 | 48.3 | 26.9 | 57 | 57 |

| 40x25 | 1″1/2x1″ | 48.3 | 33.7 | 57 | 57 |

| 40x32 | 1″1/2x1″1/4 | 48.3 | 42.4 | 57 | 57 |

| 50x20 | 2″x3/4 | 60.3 | 26.9 | 64 | 44 |

| 50x25 | 2″x1″ | 60.3 | 33.7 | 64 | 51 |

| 50x32 | 2″x1″1/4 | 60.3 | 42.4 | 64 | 57 |

| 50x40 | 2″x1″1/2 | 60.3 | 48.3 | 64 | 60 |

| 65x25 | 2″1/2x1″ | 73.0 | 33.7 | 76 | 57 |

| 65x32 | 2″1/2x1″1/4 | 73.0 | 42.4 | 76 | 64 |

| 65x40 | 2″1/2x1″1/2 | 73.0 | 48.3 | 76 | 67 |

| 65x50 | 2″1/2x2″ | 73.0 | 60.3 | 76 | 70 |

| 80x32 | 3″x1″1/4 | 88.9 | 42.4 | 86 | 70 |

| 80x40 | 3″x1″1/2 | 88.9 | 48.3 | 86 | 73 |

| 80x50 | 3″x2″ | 88.9 | 60.3 | 86 | 76 |

| 80x65 | 3″x2″1/2 | 88.9 | 73.0 | 86 | 83 |

| 90x40 | 3″1/2x1″1/2 | ||||

| 90x50 | 3″1/2x2″ | ||||

| 90x65 | 3″1/2x2″1/2 | ||||

| 90x80 | 3″1/2x3″ | ||||

| 42″x42″ | |||||

| 44″x44″ | |||||

| 46″x46″ | |||||

| 48″x48″ | |||||

| 52″x52″ | |||||

| 56″x56″ | |||||

| 60″x60″ |

Knowledge Expansion

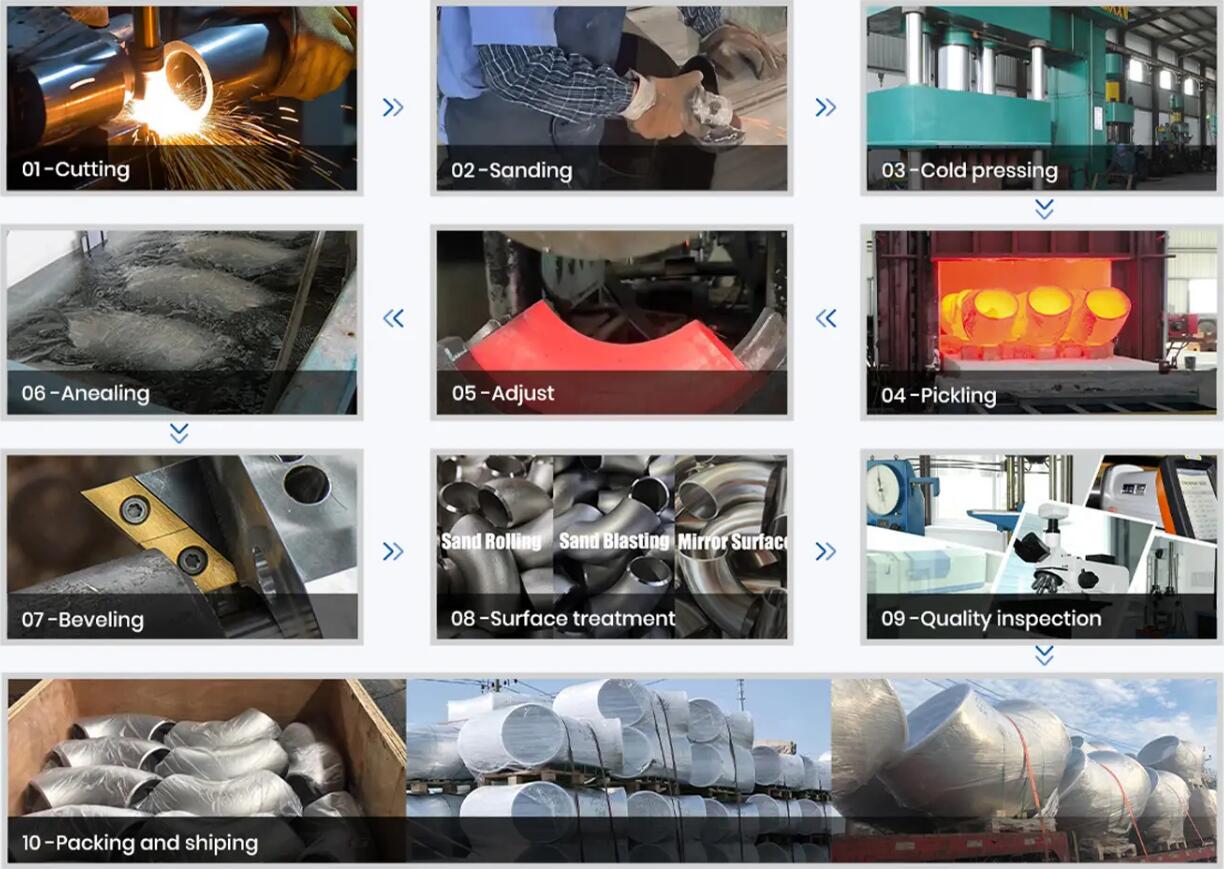

Manufacturing process of stainless steel tee

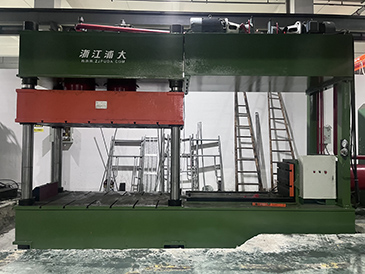

Hydraulic Bulge Method (Cold Forming)

Hydraulic bulging of stainless steel tees is a forming process that expands branch pipes through axial compensation of metal materials. The process is to use a special hydraulic press to inject liquid into the tube blank with the same diameter as the tee, and squeeze the tube blank through the synchronous centering movement of the two horizontal side cylinders of the hydraulic press. The volume of the tube blank becomes smaller after being squeezed, and the inside of the tube blank becomes smaller. The pressure of the liquid increases as the volume of the tube becomes smaller. When the pressure required for the expansion of the stainless steel tee branch is reached, the metal material flows along the inner cavity of the mold under the dual action of the liquid pressure in the side cylinder and the tube and expands the branch......

For details, click "Manufacturing process of stainless steel tee"Factory Profile

Factory exterior

10,000+㎡Factory area/30+ years of stainless steel production experience

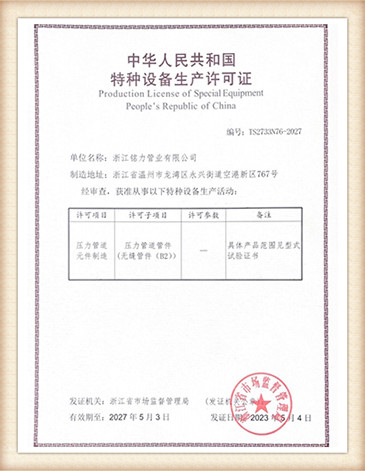

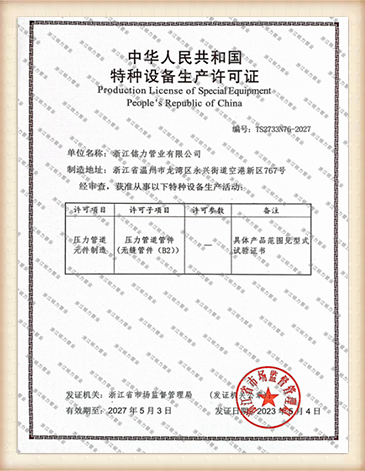

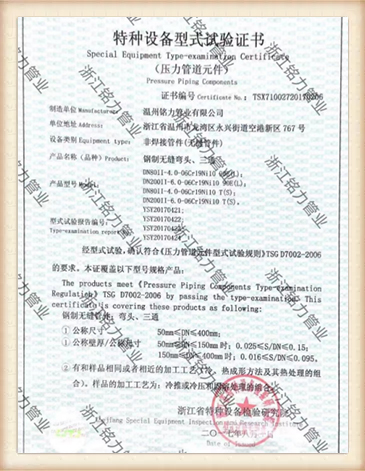

certificate display

Production line display

Production caliber: DN15-DN2500

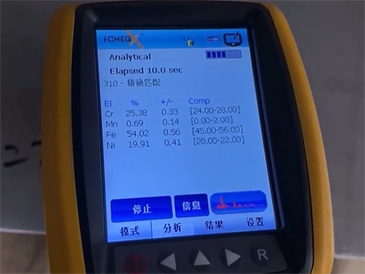

Product testing display

Support third party detection

Spot inventory display

800+ tons in stock, fast delivery

Delivery display

Ensure beautiful delivery of products