Stainless Steel Butt Weld Eccentric Reducers

Video Introduction

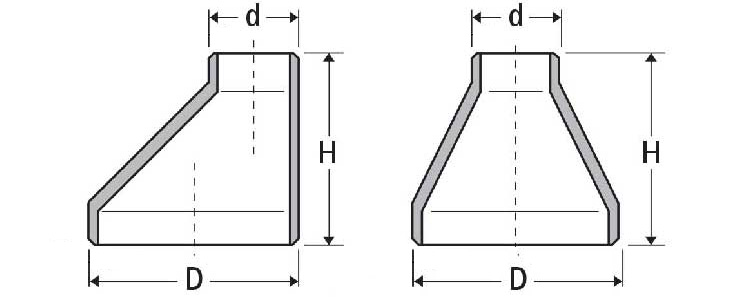

| Product Name | Stainless Steel Butt Weld Eccentric Reducers |

| Standard | ASTM A213, ASTM A312, ASTM A789, ASTM A790 |

| Material Grade | 304/316L/2205 etc. |

| NPS | 3/4″-60″ |

| Outer Diameter | 26.9mm-1524mm |

| Thickness | 2mm-20mm |

| Connection method | Butt Welded |

| Surface | Sand blasting/Sand rolling |

| Brushed/Mirror:400#, 600#, 800# or more | |

| Packing | Plastic bag/woven packing |

| Woven bags/Wooden boxes and other packaging methods. |

Product Introduction

| D-d | H/mm | ||

| DN | NPS | OD/mm | |

| 20-10 | 3/4-3/8 | 26.9-17.2 | 38 |

| 20-15 | 3/4-1/2 | 26.9-21.3 | 38 |

| 25-15 | 1″-1/2 | 33.7-21.3 | 51 |

| 25-20 | 1″-3/4 | 33.7-26.9 | 51 |

| 32-15 | 1″ 1/4-1/2 | 42.4-21.3 | 51 |

| 32-20 | 1″ 1/4-3/4 | 42.4-26.9 | 51 |

| 32-25 | 1″ 1/4-1″ | 42.4-33.7 | 51 |

| 40-15 | 1″ 1/2-1/2 | 48.3-21.3 | 64 |

| 40-20 | 1″ 1/2-3/4 | 48.3-26.9 | 64 |

| 40-25 | 1″ 1/2-1″ | 48.3-33.7 | 64 |

| 40-32 | 1″ 1/2-1″ 1/4 | 48.3-42.4 | 64 |

| 50-20 | 2″-3/4 | 60.3-26.9 | 76 |

| 50-25 | 2″-1″ | 60.3-33.7 | 76 |

| 50-32 | 2″-1″ 1/4 | 60.3-42.4 | 76 |

| 50-40 | 2″-1″ 1/2 | 60.3-48.3 | 76 |

| 65-25 | 2″ 1/2-1″ | 76.1-33.7 | 90 |

| 65-32 | 2″ 1/2-1″ 1/4 | 76.1-42.4 | 90 |

| 65-40 | 2″ 1/2-1″ 1/2 | 76.1-48.3 | 90 |

| 65-50 | 2″ 1/2-2″ | 76.1-60.3 | 90 |

| 80-32 | 3″-1″ 1/4 | 88.9-42.4 | 90 |

| 80-40 | 3″-1″ 1/2 | 88.9-48.3 | 90 |

| 80-50 | 3″-2″ | 88.9-60.3 | 90 |

| 80-65 | 3″-2″ 1/2 | 88.9-76.1 | 90 |

| 90-40 | 3″ 1/2-1″ 1/4 | 101.6-42.4 | 102 |

| 90-50 | 3″ 1/2-1″ 1/2 | 101.6-48.3 | 102 |

| 90-65 | 3″ 1/2-2″ | 101.6-60.3 | 102 |

| 90-80 | 3″ 1/2-2″ 1/2 | 101.6-73.0 | 102 |

| 100-40 | 4″-1″ 1/2 | 114.3-48.3 | 102 |

| 100-50 | 4″-2″ | 114.3-60.3 | 102 |

| 100-65 | 4″-2″ 1/2 | 114.3-73.0 | 102 |

| 100-80 | 4″-3″ | 114.3-88.9 | 102 |

| 100-90 | 4″-3″ 1/2 | 114.3-101.6 | 102 |

| 125-50 | 5″-2″ | 141.3-60.3 | 127 |

| 125-65 | 5″-2″1/2 | 141.3-73.0 | 127 |

| 125-80 | 5″-3″ | 141.3-88.9 | 127 |

| 125-90 | 5″-3″1/2 | 141.3-101.6 | 127 |

| 125-100 | 5″-4″ | 141.3-114.3 | 127 |

| 150-65 | 6″-2″ 1/2 | 168.3-73.0 | 140 |

| 150-80 | 6″-3″ | 168.3-88.9 | 140 |

| 150-90 | 6″-3″ 1/2 | 168.3-101.6 | 140 |

| 150-100 | 6″-4″ | 168.3-114.3 | 140 |

| 150-125 | 6″-5″ | 168.3-141.3 | 140 |

| 200-90 | 8″-3″ 1/2 | 219.1-101.6 | 152 |

| 200-100 | 8″-4″ | 219.1-114.3 | 152 |

| 200-125 | 8″-5″ | 219.1-141.3 | 152 |

| 200-150 | 8″-6″ | 219.1-168.3 | 152 |

| 250-100 | 10″-4″ | 273.0-114.3 | 178 |

| 250-125 | 10″-5″ | 273.0-141.3 | 178 |

| 250-150 | 10″-6″ | 273.0-168.3 | 178 |

| 250-200 | 10″-8″ | 273.0-219.1 | 178 |

| 300-125 | 12″-5″ | 323.9-141.3 | 203 |

| 300-150 | 12″-6″ | 323.9-168.3 | 203 |

| 300-200 | 12″-8″ | 323.9-219.1 | 203 |

| 300-250 | 12″-10″ | 323.9-273.0 | 203 |

| 350-150 | 14″-6″ | 355.6-168.3 | 330 |

| 350-200 | 14″-8″ | 355.6-219.1 | 330 |

| 350-250 | 14″-10″ | 355.6-273.0 | 330 |

| 350-300 | 14″-12″ | 355.6-323.9 | 330 |

| 400-200 | 16″-8″ | 406.4-219.1 | 356 |

| 400-250 | 16″-10″ | 406.4-273.0 | 356 |

| 400-300 | 16″-12″ | 406.4-323.9 | 356 |

| 400-350 | 16″-14″ | 406.4-355.6 | 356 |

| 450-250 | 18″-10″ | 457-273.0 | 381 |

| 450-300 | 18″-12″ | 457-323.9 | 381 |

| 450-350 | 18″-14″ | 457-355.6 | 381 |

| 450-400 | 18″-16″ | 457-406.4 | 381 |

| 500-300 | 20″-12″ | 508-323.9 | 508 |

| 500-350 | 20″-14″ | 508-355.6 | 508 |

| 500-400 | 20″-16″ | 508-406.4 | 508 |

| 500-450 | 20″-18″ | 508-457 | 508 |

| 550-350 | 22″-14″ | 559-355.6 | 508 |

| 550-400 | 22″-16″ | 559-406.4 | 508 |

| 550-450 | 22″-18″ | 559-457 | 508 |

| 550-500 | 22″-20″ | 559-508 | 508 |

| 600-400 | 24″-16″ | 610-406.4 | 508 |

| 600-450 | 24″-18″ | 610-457 | 508 |

| 600-500 | 24″-20″ | 610-508 | 508 |

| 600-550 | 24″-22″ | 610-559 | 508 |

| 650-450 | 26″-18″ | 660-457 | 610 |

| 650-500 | 26″-20″ | 660-508 | 610 |

| 650-550 | 26″-22″ | 660-559 | 610 |

| 650-600 | 26″-24″ | 660-610 | 610 |

| 700-500 | 28″-20″ | 711-508 | 610 |

| 700-550 | 28″-22″ | 711-559 | 610 |

| 700-600 | 28″-24″ | 711-610 | 610 |

| 700-650 | 28″-26″ | 711-660 | 610 |

| 750-550 | 30″-22″ | 762-559 | 610 |

| 750-600 | 30″-24″ | 762-610 | 610 |

| 750-650 | 30″-26″ | 762-660 | 610 |

| 750-700 | 30″-28″ | 762-711 | 610 |

| 800-600 | 32″-24″ | 813-610 | 610 |

| 800-650 | 32″-26″ | 813-660 | 610 |

| 800-700 | 32″-28″ | 813-711 | 610 |

| 800-750 | 32″-30″ | 813-762 | 610 |

| 850-650 | 34″-26″ | 864-660 | 610 |

| 850-700 | 34″-28″ | 864-711 | 610 |

| 850-750 | 34″-30″ | 864-762 | 610 |

| 850-800 | 34″-32″ | 864-813 | 610 |

| 900-650 | 36″-26″ | 914-660 | 610 |

| 900-700 | 36″-28″ | 914-711 | 610 |

| 900-750 | 36″-30″ | 914-762 | 610 |

| 900-800 | 36″-32″ | 914-813 | 610 |

| 900-850 | 36″-34″ | 914-864 | 610 |

See more sizes here

Knowledge Expansion

Since one side of the eccentric large and small heads is flat, it is conducive to exhaust or liquid drainage, and is convenient for driving and maintenance. Therefore, horizontally installed liquid pipelines generally use eccentric reducers.

When the tangent point of the nozzle of the eccentric large and small heads is upward, it is called top-flat installation, which is generally used for the pump inlet, which is convenient for exhaust; when the tangent point is downward, it is called bottom-flat installation, which is generally used for the installation of regulating valves and uses drain.

There are only two types of large and small heads: concentric and eccentric. Flat top and flat bottom are just an installation method for eccentric and large heads.

For details, click "Installation method of eccentric stainless steel reducer"Factory Profile

Factory exterior

10,000+㎡Factory area/30+ years of stainless steel production experience

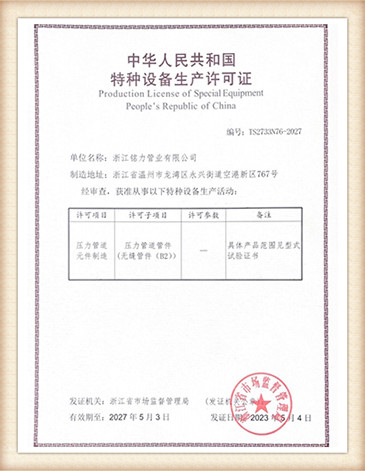

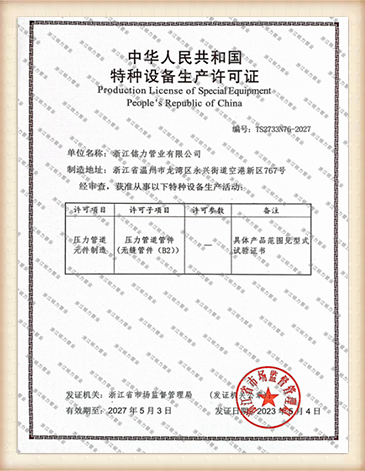

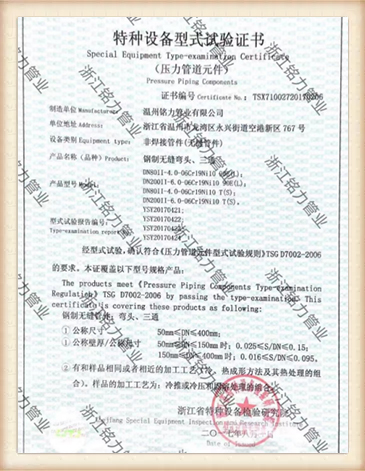

certificate display

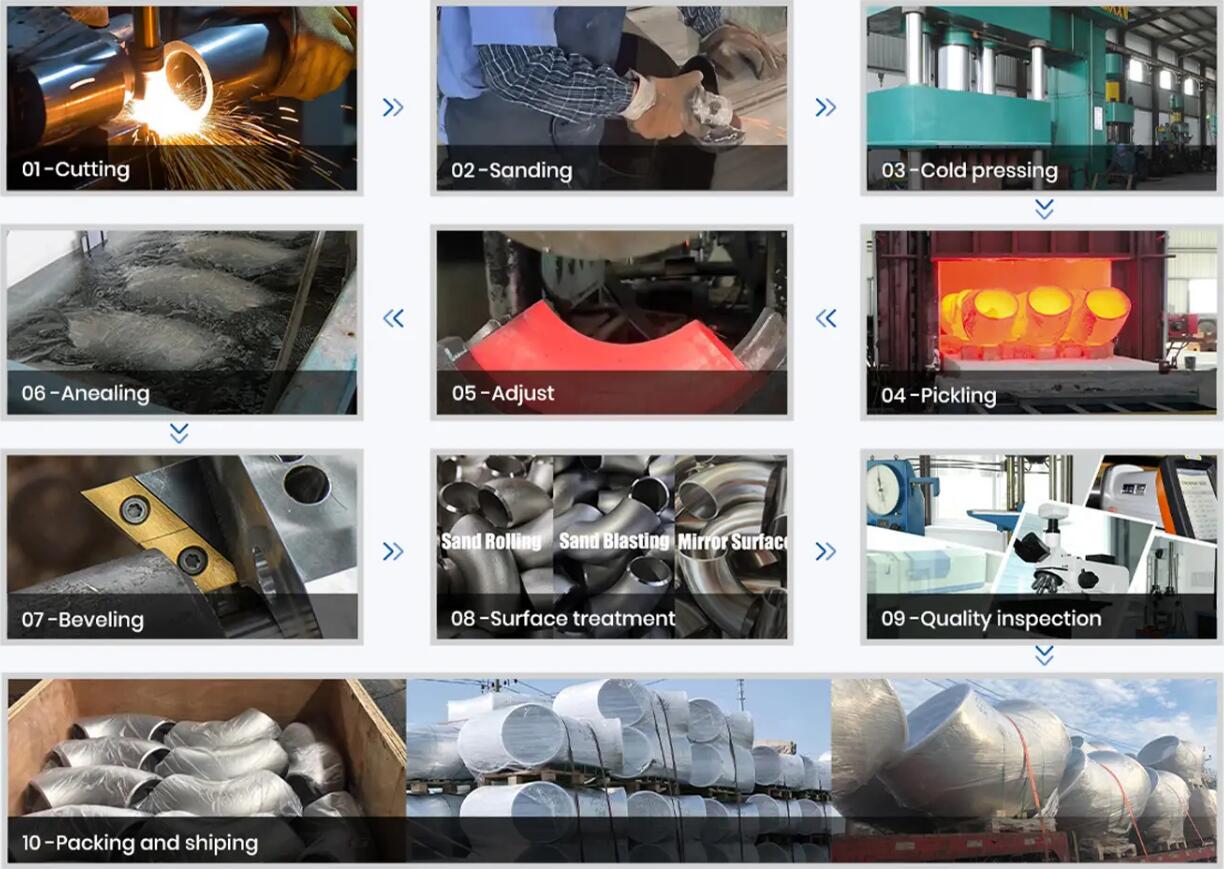

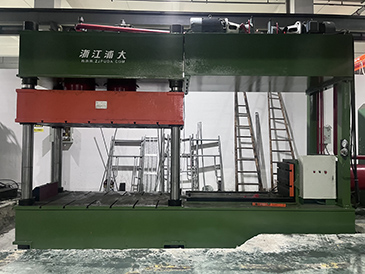

Production line display

Production caliber: DN15-DN2500

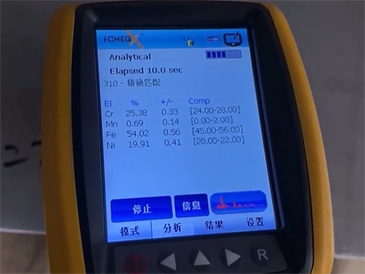

Product testing display

Support third party detection

Spot inventory display

800+ tons in stock, fast delivery

Delivery display

Ensure beautiful delivery of products