How to choose high-quality stainless steel pipe fittings (such as stainless steel elbows)-the difference between intermediate frequency furnace and refining furnace

Abstract: This article aims to help customers learn and differentiate between stainless steel pipes produced by intermediate frequency furnaces and stainless steel pipes produced by refining furnaces, so that they can choose better quality stainless steel pipe fittings (such as stainless steel elbows).

At present, stainless steel pipes on the market are generally divided into refining furnace production and intermediate frequency furnace production, so what is the difference between the two?

1. Different production processes

When refining stainless steel pipes, the refining furnace will blow oxygen, inert gases argon (Ar) and nitrogen (N2) into the molten steel to achieve a false vacuum effect, which will reduce the carbon content in the stainless steel pipes to very low levels. , and blowing in inert gas at the same time can also inhibit the oxidation of chromium alloy elements in stainless steel.

The intermediate frequency furnace generates a magnetic field through alternating current to heat the metal in the furnace for steelmaking. When using an intermediate frequency furnace to produce stainless steel pipes, the carbon content cannot be reduced and impurities cannot be removed.

2: Different processing characteristics

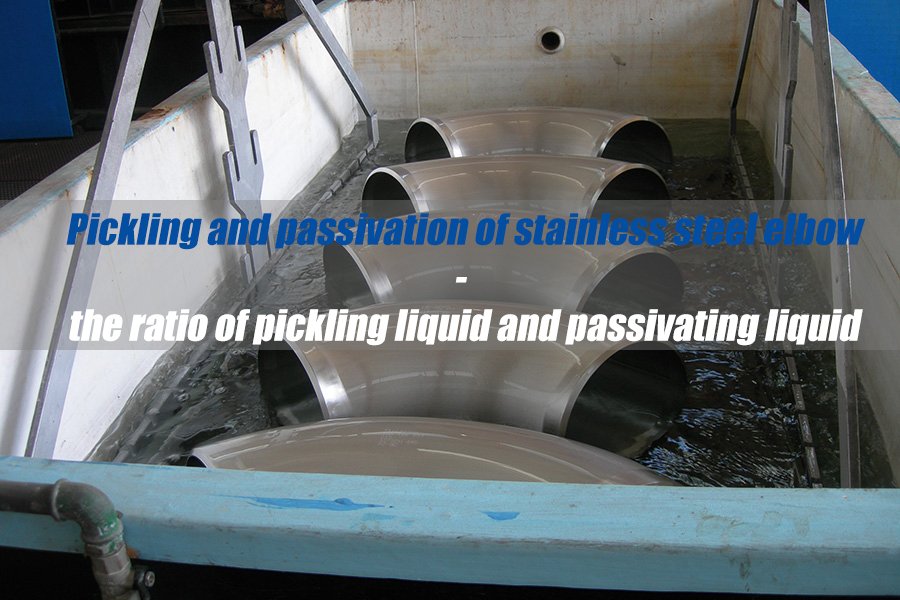

The stainless steel pipes produced by the refining furnace have low carbon content and few impurities, and can well retain useful alloying elements such as chromium. Therefore, the stainless steel pipes produced by the refining furnace have high ductility and can perfectly complete complex processing such as bending, bending, expanding, shrinking, etc., to meet the processing needs of stainless steel pipe fittings, and because of their low impurities, they can be Complete the high-demand surface polishing processing of stainless steel pipe fittings (such as stainless steel elbows).

Stainless steel pipes made by medium-frequency furnaces have poor ductility and poor processing performance in bending, bending, expanding, and shrinking. The impurity content in stainless steel pipes is high, and they cannot meet the requirements for fine polishing of high-quality stainless steel pipe fittings (such as stainless steel elbows).

Three: different raw materials

The refining furnace can perform secondary steelmaking, and generally can flexibly add or reduce relevant elements to achieve the purpose of refining, so scrap iron and iron sand are generally used as raw materials.

The intermediate frequency furnace can only make steel once, especially in terms of raw materials, which cannot be flexibly controlled, so stainless steel scrap and iron sand are generally used for smelting. This smelting method cannot control the content of certain elements, so the product quality is relatively poor and is generally not used in product industries such as deep processing.

Zhejiang Mingli Pipe Industry is a Chinese stainless steel pipe fittings factory with more than 30 years of production and processing experience. The raw materials are 100% refined furnace steel pipes, ensuring the quality from the source.