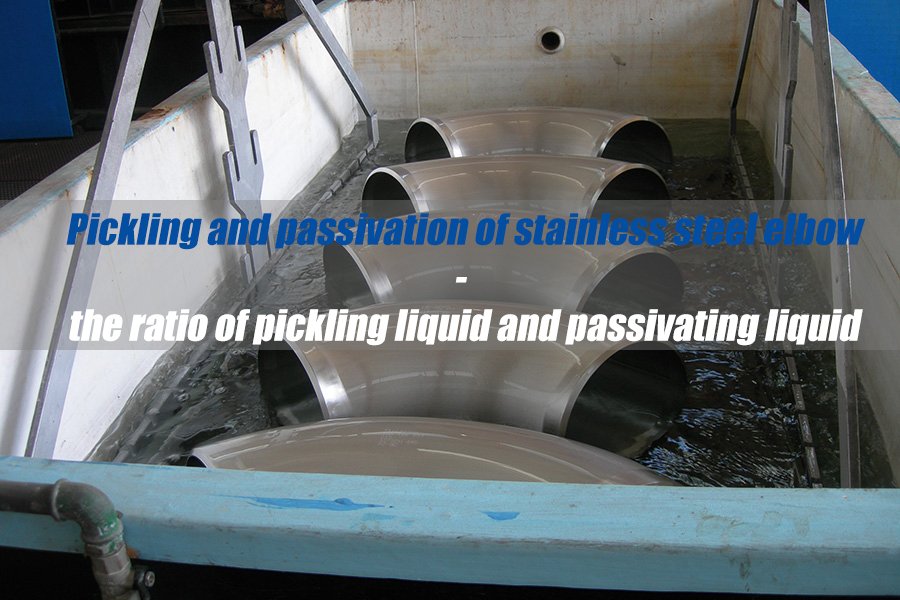

Pickling and passivation of stainless steel elbow - the ratio of pickling liquid and passivating liquid

What is pickling and passivation treatment of stainless steel elbow ?

Black and yellow oxide scales will appear during the processing of stainless steel elbow. In order to improve the appearance and corrosion resistance of stainless steel elbow, the processed stainless steel elbow must be pickled and passivated. Stainless steel elbow pickling is to remove the oxide scale produced after welding and high-temperature processing to make the bright and shiny. Stainless steel elbow passivation is to form an oxide film with chromium as the main substance on the treated surface to prevent secondary oxidation, thereby improving the surface anti-corrosion quality of stainless steel elbow and extending the service life of the equipment.

Pickling and passivation of stainless steel pipe fittings are generally treated with pickling passivation paste and pickling passivation liquid. Pickling passivation paste synchronizes pickling and passivation and completes it in one step, changing the traditional pickling and passivation process. Chemical technology, simple operation, convenient construction and low cost. Suitable for painting large area and large diameter stainless steel pipe fittings. The pickling passivation solution is suitable for the soaking operation of small diameter stainless steel pipe fittings.

Let’s talk about the mixing ratio of commonly used pickling liquids and passivating liquids for stainless steel pipe fittings. Pickling liquid, passivation liquid and pickling paste formula

Pickling solution: 20% nitric acid + 5% hydrofluoric acid + 75% water

Passivation solution: 5% nitric acid + 2% potassium dichromate + 93% water

Steps to use stainless steel pickling passivation solution:

1. Treat the oil stains on the surface of the stainless steel elbow and polish it;

2. Pour the passivation solution into a plastic container. Depending on the material of the stainless steel elbow and the degree of oxidation, you can use the original solution or dilute it in a ratio of 1:1-4 before use;

3. Soak the stainless steel elbow to be treated in the liquid, usually at normal temperature, or it can be heated to 40-50 degrees for processing. The soaking time is 3-20 minutes or more, and the specific time and temperature can be determined according to the actual situation;

4. Until the dirt on the surface of the stainless steel elbow is completely removed and appears uniformly bright silvery white, which means the pickling and passivation is completed, take out the stainless steel elbow, rinse it with clean water, and dry it.

After pickling and passivation treatment of stainless steel pipe fittings, it will not affect the conductivity of the material, change the material composition, or affect the bonding properties such as spraying.