Versatility and Durability of Stainless Steel Flanges

Stainless steel flanges are an important component in a variety of industrial applications, providing strong and reliable connections between pipes, valves and other equipment. Their versatility and durability make them a popular choice in industries ranging from oil and gas to chemical processing and water treatment. In this blog, we will explore the many advantages of stainless steel flanges and their importance in modern engineering.

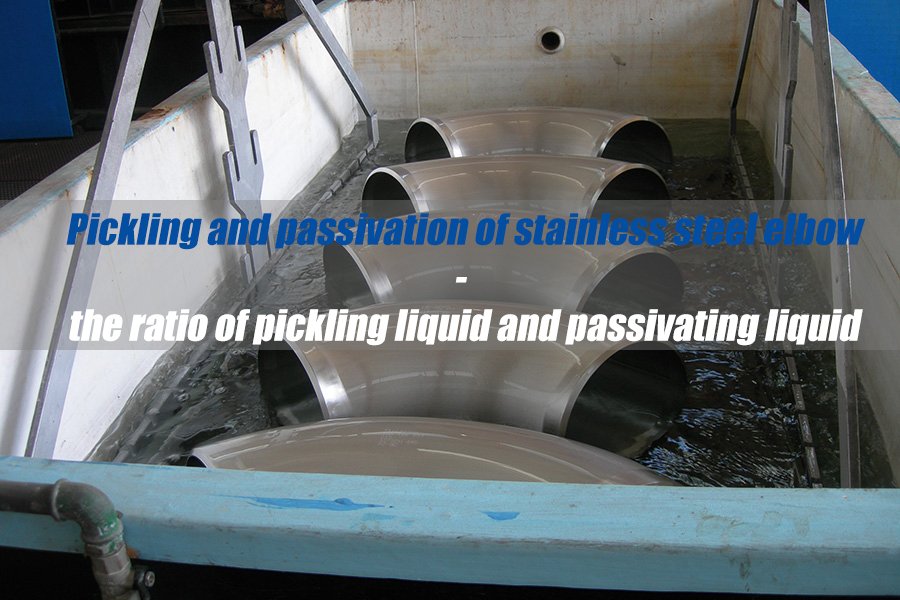

One of the main advantages of stainless steel flanges is their excellent corrosion resistance. This is especially important in industries where equipment is exposed to harsh chemicals, high temperatures and extreme pressures. Stainless steel is known for its ability to resist corrosion, making it a reliable choice for flanges that need to maintain their integrity in challenging environments. This corrosion resistance also means stainless steel flanges have a long service life, reducing the need for frequent replacement and maintenance.

In addition to being corrosion-resistant, stainless steel flanges are also extremely durable. They can withstand heavy loads and high pressures without compromising their structural integrity, making them suitable for demanding applications. This durability is a result of the inherent strength of stainless steel, allowing the flange to maintain its shape and performance even under extreme conditions. Therefore, stainless steel flanges are often used in critical systems where reliability is critical.

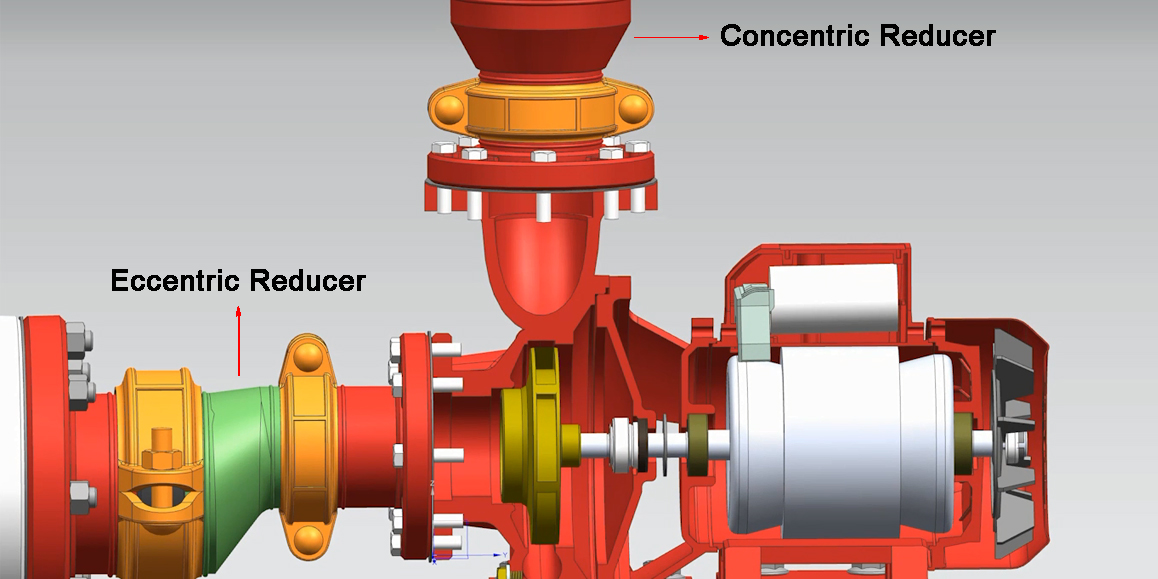

Another advantage of stainless steel flanges is their versatility. They are available in a variety of sizes, pressure ratings and configurations, making it easy to find the right flange for your specific application. Whether it is lap flange, sliding sleeve flange, butt welding flange or socket welding flange, stainless steel materials can meet the diverse needs of different industries. This versatility enables engineers and designers to select the most appropriate flange based on their specific requirements, ensuring optimal performance and safety.

Stainless steel flanges are also known for their ease of installation. They can be welded, bolted or threaded to pipes and equipment, providing safe, leak-free connections. This easy installation not only saves time and labor costs, but also ensures the flange is installed correctly, reducing the risk of leaks and failure. In addition, the stainless steel flange can be easily disassembled and reinstalled, making maintenance and repairs more convenient.

In addition, stainless steel flanges are environmentally friendly. Stainless steel is fully recyclable, making it a sustainable choice for industrial applications. By using stainless steel flanges, companies can contribute to reducing their impact on the environment and promoting a circular economy. This is consistent with the industry’s growing focus on sustainability and responsible manufacturing practices.

In summary, stainless steel flanges combine versatility, durability and corrosion resistance, making them an indispensable component in modern engineering. Their ability to withstand harsh conditions, provide secure connections and contribute to sustainability makes them the first choice for a variety of industrial applications. As the industry continues to evolve, stainless steel flanges will continue to be a key element in ensuring the reliability and safety of critical systems.

Whether in refineries, chemical plants, power generation facilities or water treatment plants, stainless steel flanges play a vital role in maintaining the integrity and performance of industrial infrastructure. Their importance cannot be overstated, and their continued use reflects the confidence that engineers and designers have in the reliability and effectiveness of stainless steel flanges. As technology advances and new challenges arise, stainless steel flanges will continue to be at the forefront of innovation and advancement in the engineering industry.